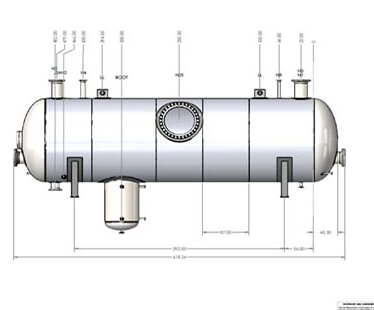

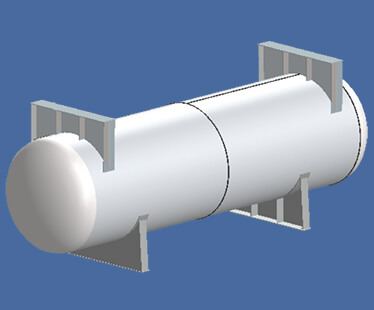

3d Pressure Vessel Design Software

Pressure Vessel Software For ASME VIII

Smarter Pressure Vessel Software

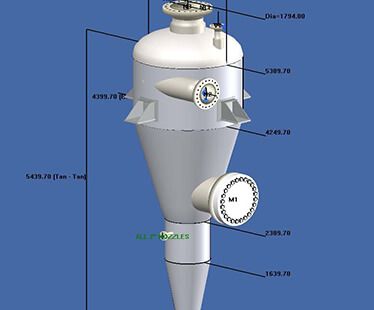

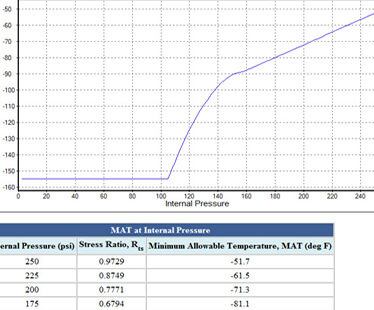

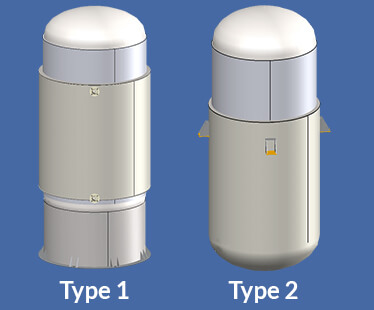

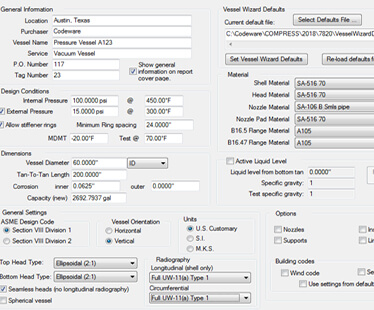

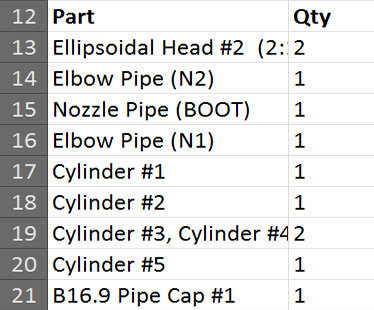

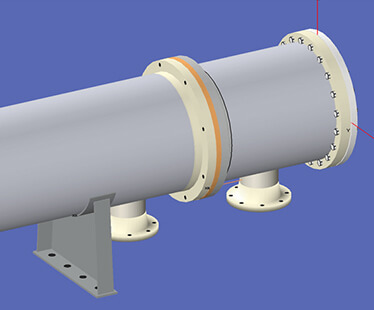

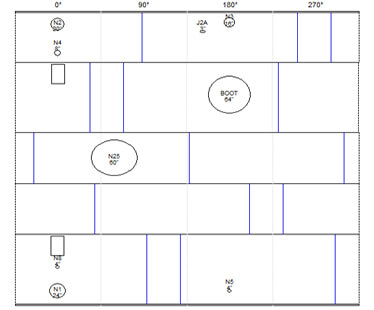

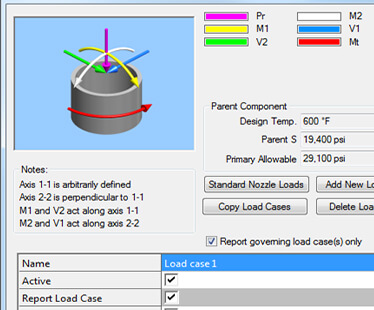

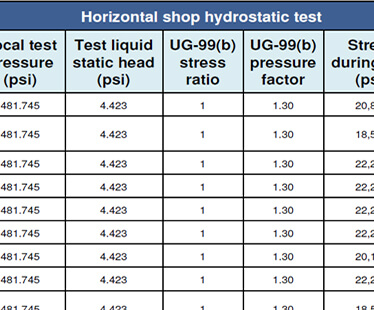

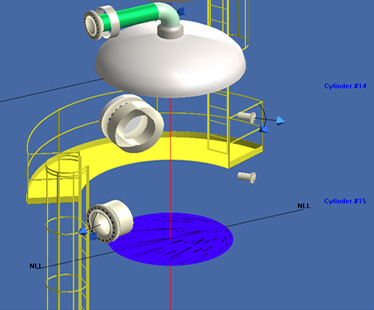

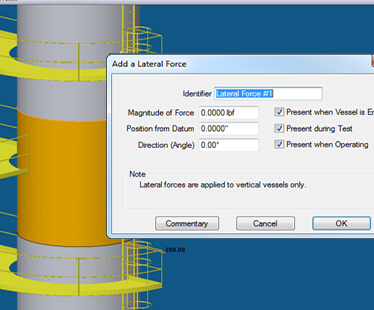

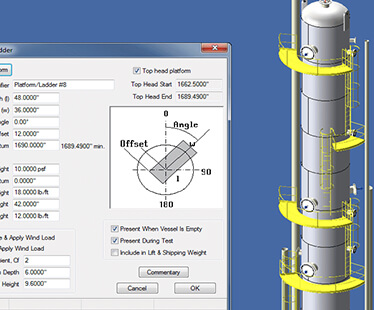

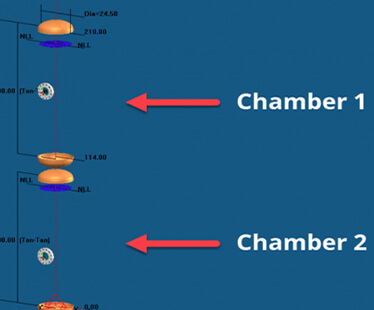

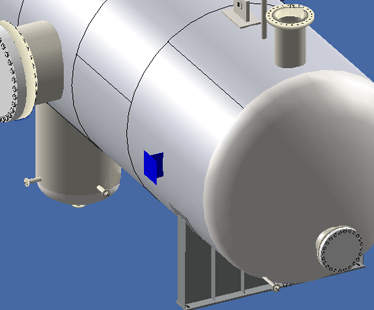

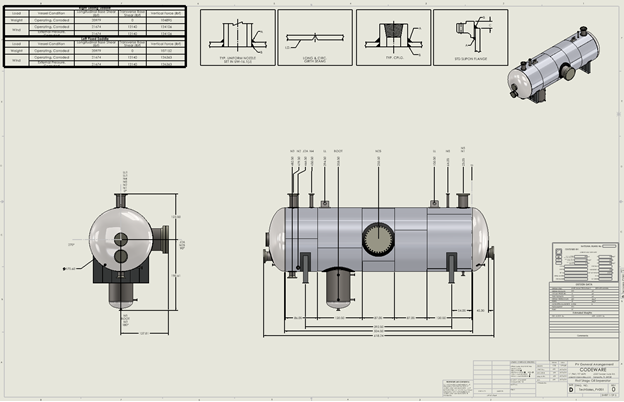

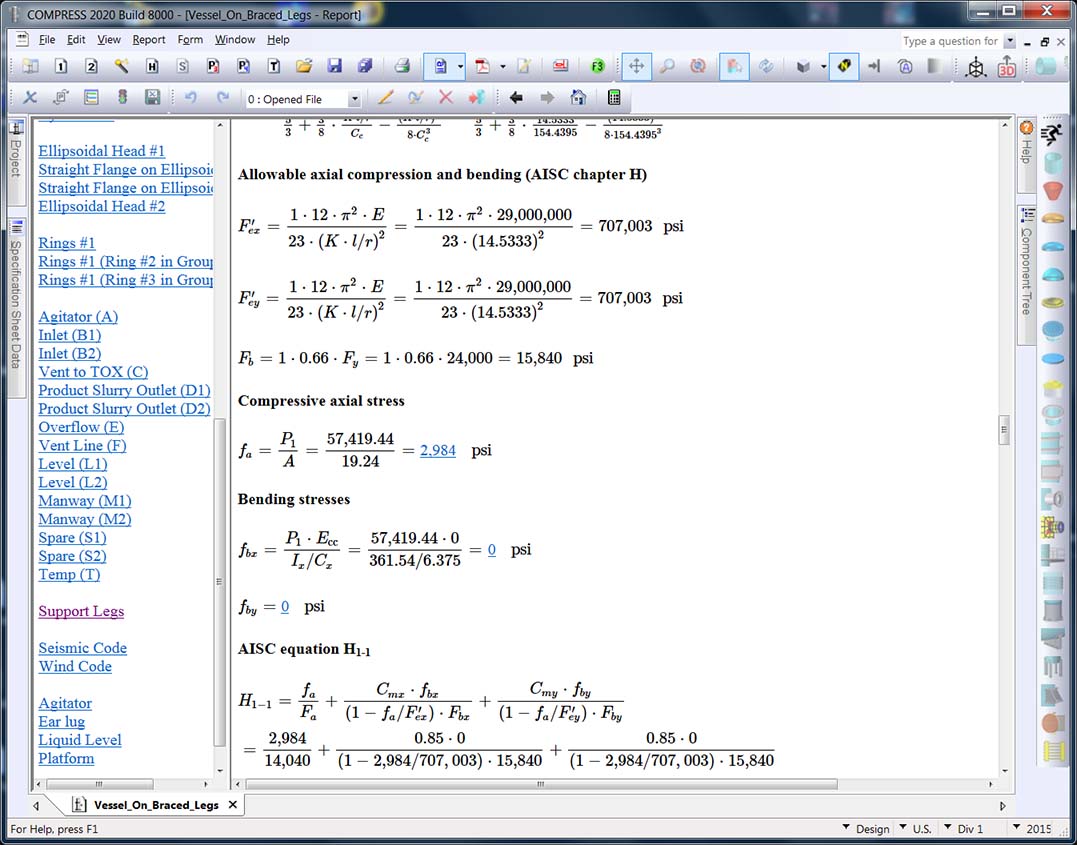

COMPRESS is an expert system that produces professional level pressure vessel design reports with a single button click. It saves engineering hours while reducing errors and omissions. COMPRESS checks your inputs and makes design recommendations. This makes it the perfect solution for companies that want to bring their design work in-house. COMPRESS automates jobs that less capable solutions require you to do. Tasks such as compiling reports, determining MDMT chart assignments, calculating hillside nozzle intersections and liquid static head determinations are handled for you. Features like solid modeling, drawings, material schemes, lift lugs, clips, and estimating come standard with COMPRESS.

We invite you to review the capabilities featured below and see why COMPRESS has set the standard in pressure vessel software for over 38 years.

Featured Pressure Vessel Design Capabilities

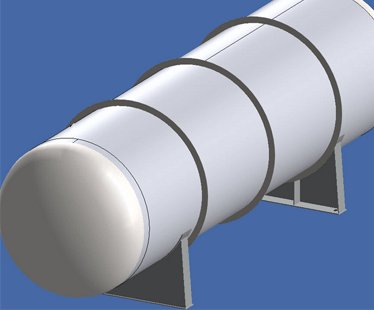

UG-28 rules for external pressure of 15psig and greater.

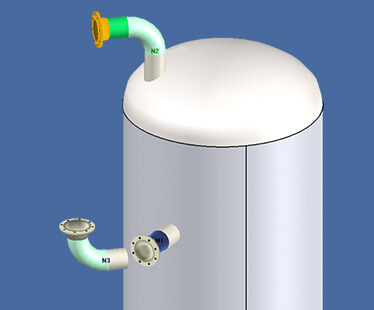

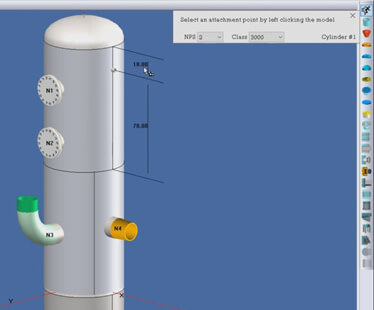

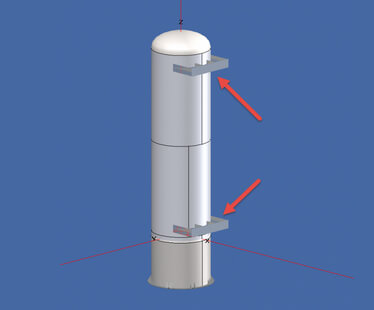

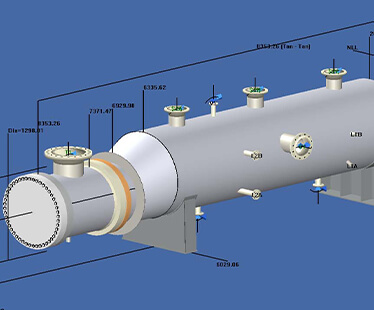

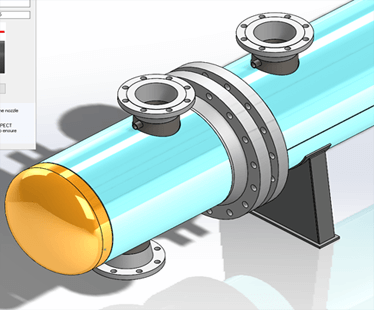

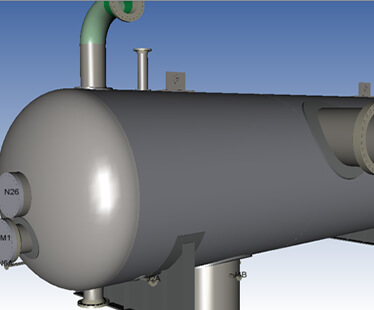

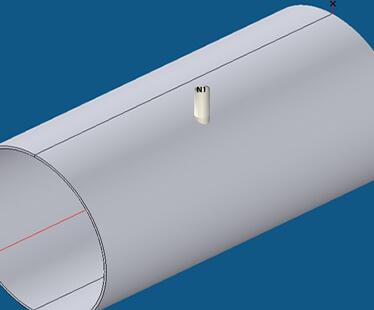

3D Pressure Vessel Design + Drawings

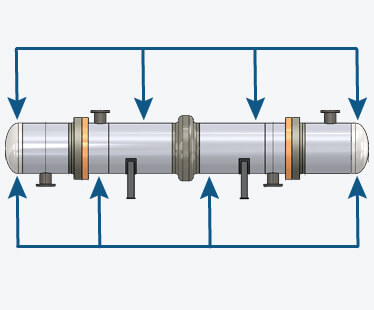

Designing pressure vessels is only part of the job. To complete the whole job, COMPRESS supports cross-departmental workflows:

-

Efficiently produce pressure vessel and heat exchanger drawings using the bundled Codeware Interface® add-in for SOLIDWORKS® and Inventor®. Solid models generated by the Codeware Interface include Mates and Sheet Metal, advanced features that save time when making design changes.

-

Quickly create ASME® Section IX welding documents from COMPRESS designs with Shopfloor®.

-

Generate customizable spreadsheet based cost estimates with the no extra charge COSTER® add-in for Excel®.

Supporting You is Our #1 Priority

-

We are committed to providing industry-leading service to our clients. We know that you're not only committing to our pressure vessel software as it is today but trusting that we'll provide what you need in the future.

-

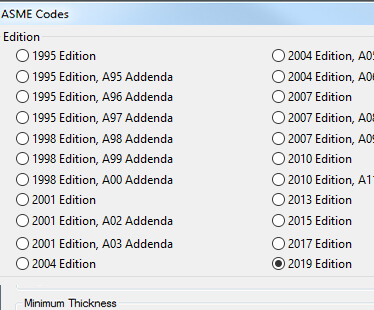

You can rely on us to preserve your pressure vessel software investment by introducing new capabilities and keeping up with ASME VIII changes. With our support service you'll typically receive two software updates a year. We are committed to providing our valued customers with pressure vessel software that 1) complies with the ASME Code and 2) increases productivity to make your business more profitable.

-

We have a dedicated support team with deep pressure vessel design expertise ready to help you. Our support team includes Mechanical Engineers, IT Technical Support Analysts and Account Managers.

"In our 20 plus years of using COMPRESS including the design, quotation and fabrication of in excess of 10,000 pressure vessels, we have come to rely on the accuracy and dependability we get each and every time."

"We have been using COMPRESS since its inception. Les Bildy has developed a first rate product.

We have found it very user friendly, and can't imagine our company succeeding

without it."

Recent COMPRESS Feature Additions

- Flange Bolt Loads per WRC-538

- Nozzle Type UW-16.1, Sketch BB

Find Out More

- Español

3d Pressure Vessel Design Software

Source: https://www.codeware.com/products/compress/

Posted by: parisibehisellin.blogspot.com

0 Response to "3d Pressure Vessel Design Software"

Post a Comment